POX Hub

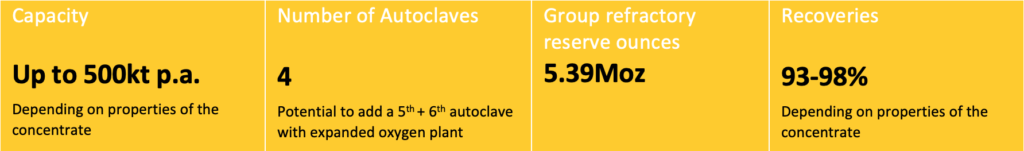

Key Facts

At a glance statistics

Overview

Regarded as the future of gold industry in Russia, the Pressure Oxidation facility (‘POX Hub’) is one of the most technologically advanced processing plants of its kind, as well as being Petropavlovsk’s newest and most important asset.

Pressure oxidation technology is the most efficient and environmentally-friendly technology for processing refractory gold ore and enables the Group to unlock the value embedded within c.5.31Moz of its own refractory reserves (including double-refractory ore), as well as treat 3rd party refractory material and future potential to exploit high-quality refractory orebodies across Russia and further afield.

The POX Hub is strategically located at the site of the Company’s first and now depleted mine, Pokrovskiy, where it benefits from existing milling facilities, road and rail infrastructure, low cost renewable power (hydroelectric) as well as a nearby limestone deposit – a key ingredient in the POX process.

The plant is one of only two in Russia and its rail connectivity means it has the potential to unlock the value of Russia’s significant refractory resource base which accounts for approximately 40% of total resources. Many of these resources are high quality and under explored given the lack of processing capacity in the country.

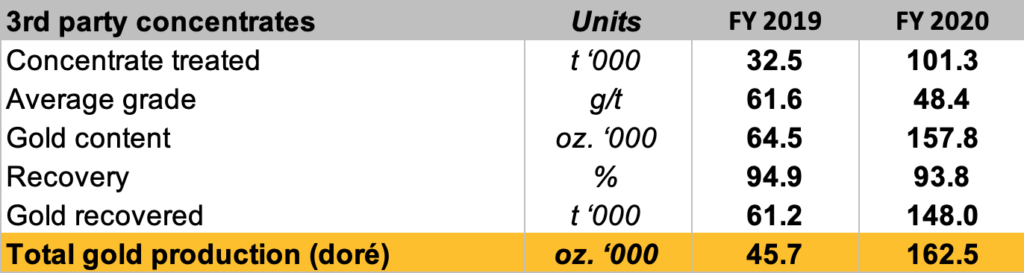

Launched at the end of 2018, the 500kt p.a. plant has ramped up smoothly, initially treating refractory gold concentrates from the Malomir mine and 3rd party concentrates. From the fourth quarter of 2020, the POX Hub will begin treating concentrates from the Group’s second refractory gold mine Pioneer.

Operations

Refractory processing flowsheet

The POX Hub

The Pressure Oxidation facility (‘POX Hub’) is a cornerstone of Petropavlovsk’s strategy and the principal driver of future value for the Company. The ability to process previously untreatable refractory ores, where gold is locked in sulphides, has opened a swathe of new opportunities for the Group to exploit both in the short and long term.

In the short term, the POX Hub and associated flotation infrastructure at Malomir has unlocked the value of refractory gold which forms c. 60% of the Group’s current resource base. The optimisation of the Malomir flotation plant has increased the concentrate grade while lowering the volume of concentrate material sent to the POX Hub, thus reducing transportation and processing costs.

A further advantage of lower concentrate volumes means there will potentially be 50kt of excess annual processing capacity available at the POX Hub, based on the existing four autoclaves and fully expanded flotation plants at Malomir and Pioneer. This excess capacity can be filled with either high-grade third-party refractory concentrate or new assets outside the Group’s current portfolio.

In future, the Group may also consider adding autoclaves 5 and 6 to the POX Hub, which would increase processing capacity by an additional 30% and may be funded as a joint-venture with a partner or operated under a toll treatment style arrangement. Any incremental increase in capacity would benefit from economies of scale.

The POX process

The POX method begins with the same processes as a traditional Resin-in-pulp (‘RIP’) method where ore is mined, crushed and ground. It then passes through a flotation circuit which produces a high-grade concentrate equating to between 2.8% and 4.2% of the original mass of the ore (‘concentrate yield’). Concentrate is then transported to the POX Hub for further processing and gold recovery.

The POX Hub at Pokrovskiy is designed to operate at a pressure of 3,500kPa and at a temperature of 225°C which is higher than most other operating POX plants and enables the efficient processing of a variety of refractory feeds including double-refractory concentrates.

Four separate autoclave vessels provide a significant degree of flexibility because concentrates from Malomir, Pioneer and other sources can be processed optimally at the same time, without compromising productivity or gold recovery.

The POX Plant Flowsheet

POX processing is a series of standard and well understood technologies:

(1) A large tailings pond allows use of fresh water in quantities sufficient to prevent chlorine ion concentration build-up, thus optimising gold recovery

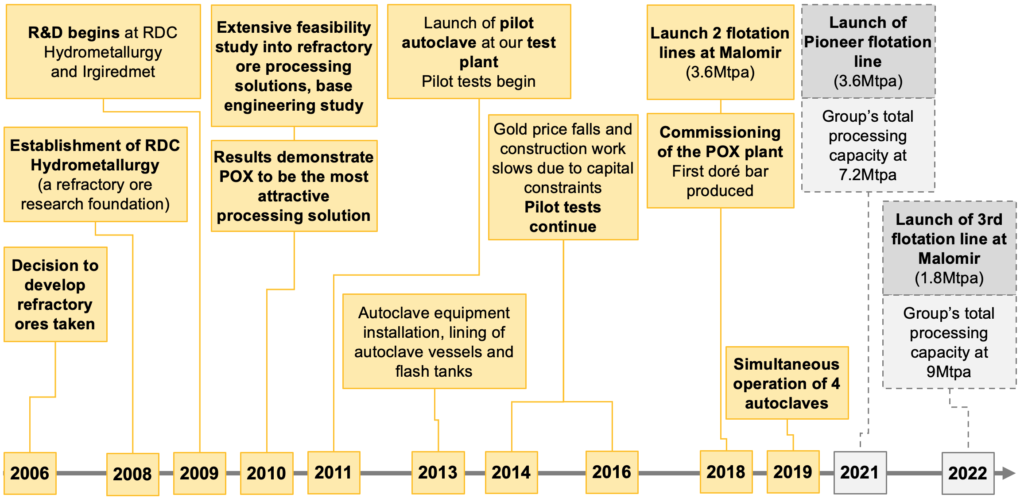

History

In 2010, following confirmation that substantial refractory gold resources existed at the Pioneer and Malomir mines, an extensive feasibility study into refractory ore processing solutions was carried out by PHM Engineering, a Petropavlovsk subsidiary. This incorporated a base engineering study prepared by Outotec, a Finnish engineering firm, in cooperation with the RDC Hydrometallurgy methodological scientific centre, another Petropavlovsk subsidiary.

The results demonstrated that POX was the most attractive processing solution in both technical and economic terms, in addition to being the safest and most environmentally friendly method.

In 2011, the Company sanctioned the development of the “POX project”. The project envisaged the construction of flotation plants at Malomir (5.4Mtpa) and Pioneer (6.0Mtpa) with a 500kt p.a. pressure oxidation facility (POX Hub) at Pokrovskiy with four separate autoclave vessels (15m x 4m, each with a volume of 66m3) and having the potential to expand capacity by adding a further two vessels.

Following a sharp fall in gold prices, the Company placed the POX Hub development program in care and maintenance in 2013, while exploring potential external funding solutions with the Company’s lenders, and other JV partners. Prior to being mothballed, significant design work, earth works, civil works and construction had been completed. Beginning in 2017, full scale development works were resumed which led to the successful commissioning of the hub in Q4 2018.